Three-dimensional structure control technology enables high-performance fuel cells with higher stability

A research team led by Dr. Yoo Sung Jong of the Hydrogen and Fuel Cell Research Center at the Korea Advanced Institute of Science and Technology (KIST) has developed a fuel cell technology with high stability over a long period of time and improved power density compared to conventional fuel cells by introducing three-dimensional structure control technology. The study is published in the journal Advanced Materials.

A three-dimensional structure is a three-dimensional arrangement of electrode layers, electrolyte membranes, and transport layers, which are necessary components for fuel cell operation, and are closely related to fuel cell performance.

Fuel cells are a technology that utilizes hydrogen, the most abundant element on Earth, to generate electricity, and are attracting attention as a clean energy source that can overcome the limitations of charging speed and storage capacity of secondary batteries.

Among the various types of fuel cells, polymer electrolyte membrane fuel cells (PEMFCs) have a high potential for commercialization because they can deliver power quickly and operate at relatively low temperatures. However, the water generated inside them during long-term operation reduces their durability and performance, hindering their commercialization.

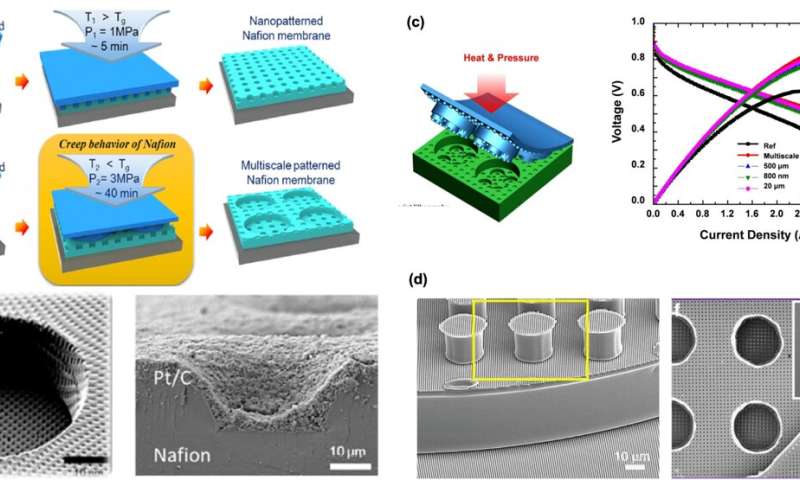

The research team developed a three-dimensional structured electrode control technology based on a multiscale architecture to manage water generation within PEMFCs. This technology combines structures of different sizes to improve the performance of fuel cells, and this study shows that designing electrode layers with multidimensional structures of one and three dimensions can solve the problem of performance degradation due to overgenerated water while utilizing existing catalysts and electrolyte membranes.

-

![Three-dimensional structure control technology enables high-performance fuel cells with higher stability]()

Designing polymeric membranes using imprinting technology to improve fuel cell performance. Credit: Korea Institute of Science and Technology

-

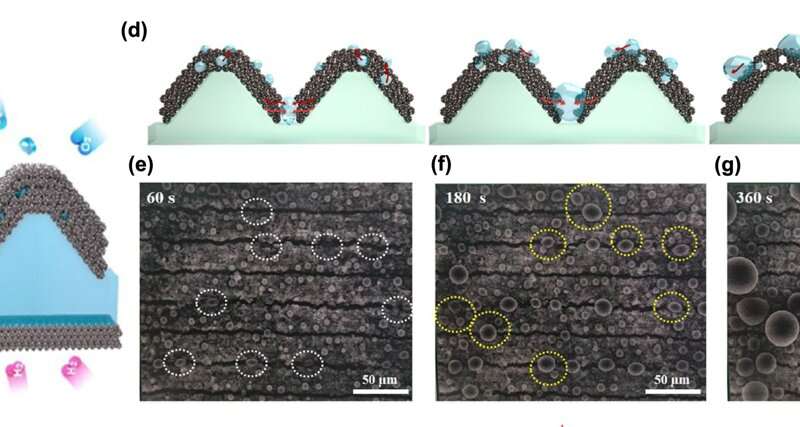

Optimization of electrode gaps to improve water management in fuel cells. Credit: Korea Institute of Science and Technology

Furthermore, by patterning the surface of the three-dimensional electrolyte membrane with a single or multi-layer structure, the researchers were able to reduce the resistance and increase the electrochemically active surface area in the fuel cell, resulting in the mechanical strength of the fuel cell has improved and the power density of the fuel cell has increased by more than 40% compared to the previous one.

The research team also developed a three-dimensional structure of the transport layer with improved mass transfer properties due to pore gradients and humidified gas diffusion. Using the high surface stress of the electrolyte membrane, the researchers found that the crack due to stretching in the electrode layer act as efficient channels for the water generated inside the cell, resulting in an 18% increase in maximum power density compared to conventional fuel cells without cracks.

“Using a three-dimensional structure, it is possible to maximize the utilization of various catalysts, which was difficult with the existing fuel cell structure, and to stably manage the generated water in PEMFCs,” said Dr. Yoo sung jong of KIST. “In the future, we expect to be able to apply new three-dimensional structures that are totally different from conventional simple structures to fuel cells for hydrogen vehicles or power generation.”

More information:

Segeun Jang et al, Multiscale Architectured Membranes, Electrodes, and Transport Layers for Next‐Generation Polymer Electrolyte Membrane Fuel Cells, Advanced Materials (2022). DOI: 10.1002/adma.202204902

Provided by

National Research Council of Science & Technology

Citation:

Three-dimensional structure control technology enables high-performance fuel cells with higher stability (2023, July 26)

retrieved 26 July 2023

from https://techxplore.com/news/2023-07-three-dimensional-technology-enables-high-performance-fuel.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.

For all the latest Technology News Click Here

For the latest news and updates, follow us on Google News.