Flashforge Adventurer 4 review: Close to an ideal 3D printer

At first glance, the FlashForge Adventurer 4 might strike 3D printing enthusiasts as a fairly boring device. it prints mostly without fuss, with few problems and quirks. My second print with the Adventurer 4 — a large bird feeder that took nearly 29 hours to print — would have scared the crap out of me a few years ago, when long, large prints were complex and likely to fail. But the Adventurer 4 handled that print without issue, producing a smooth, clean print with no hassles almost straight out of the box.

That kind of straight-ahead performance shows just how far 3D printing has come, and as I found in my FlashForge Adventurer 4 review, it makes this device an appealing option for enthusiasts looking for one of the best 3D printers that’s a few steps ahead of printers aimed at beginners. That said, printing with the FlashForge Adventurer 4 isn’t completely hassle-free, as the software that prepares your print and operates the printer itself has more than a few rough edges.

FlashForge Adventurer 4 review: Price and availability

The FlashForge Adventure 4 is available now for $799.99. That price includes four print heads and a 1kg reel of filament. You can also opt for a package with a 2kg reel ($829) or 4kg reel ($859).

The Adventure 4 costs more than some of the entry-level printers we’ve tested like the $399 Monoprice Voxel. But it’s also a more advanced device that’s a bit more affordable that some of the pro-level 3D printers that command four-figure price tags.

FlashForge Adventurer 4 review: Design

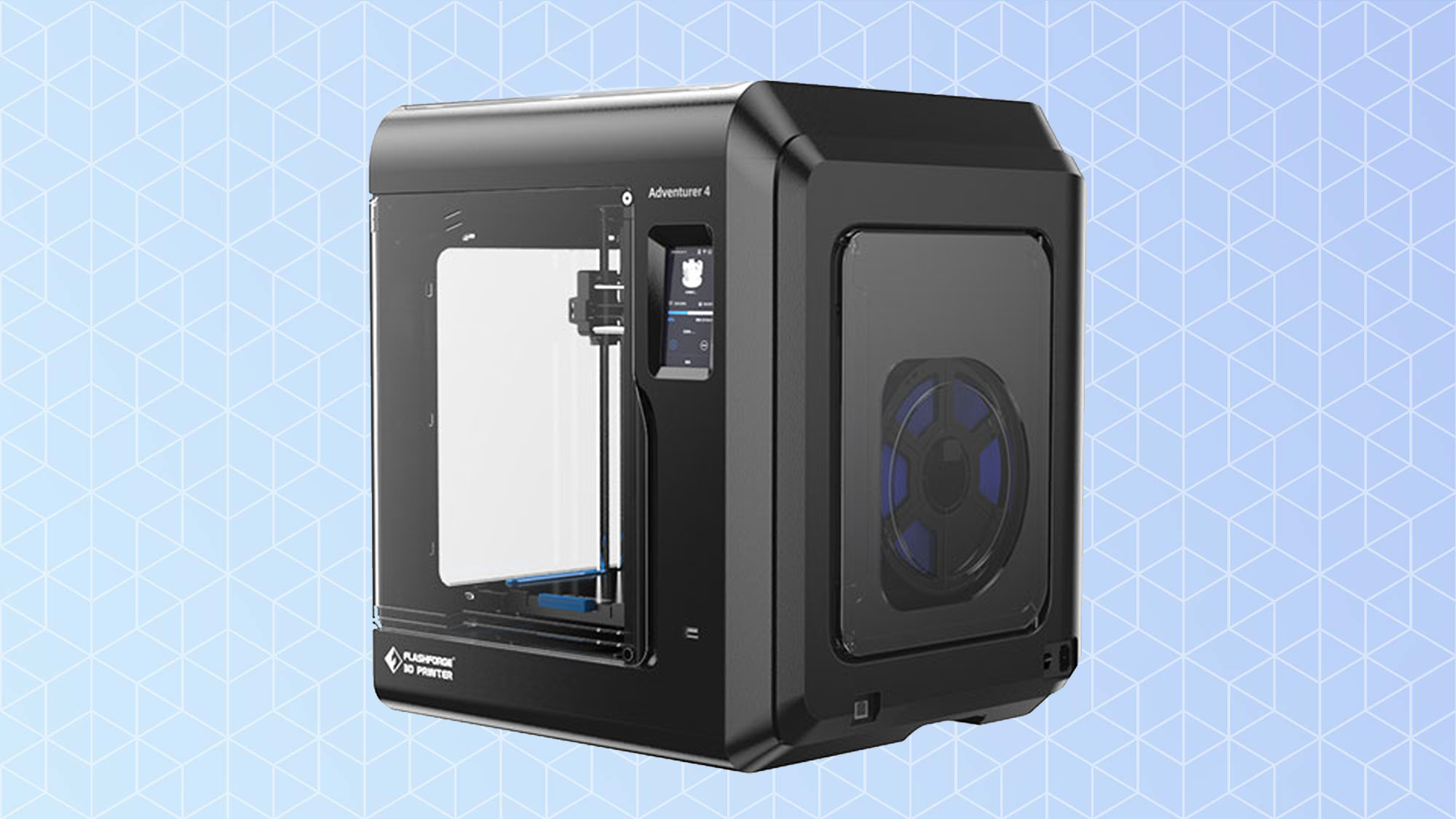

The Adventurer 4 is a large 3D printer, measuring 21.7 x 19.7 x 18.5 inches. The entire printing mechanism is enclosed, with a small fan at the back that sucks the air out through a HEPA filter. That means that printing is a lot less smelly than it can be with most 3D printers. The filter captures any small particles that are given off: a cause of concern for open 3D printers.

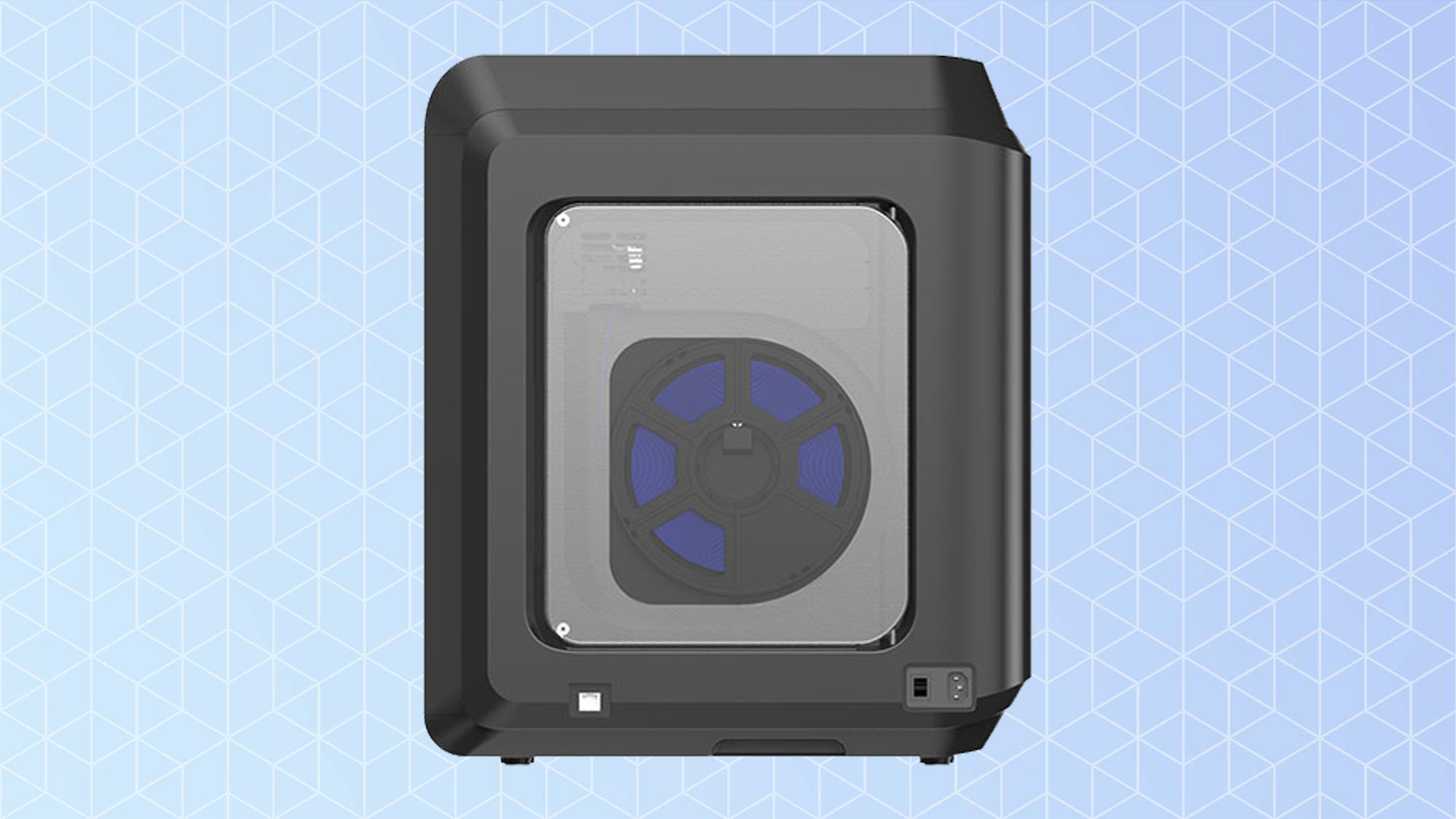

There are clear panels on the top and sides, and the front is mostly covered by a clear plastic door that opens to provide access to the print bed. On the right side is a smaller door that covers the filament reel. This means that the filament reel is also, to some degree, protected from the outside air, which can be important for materials like PLA that tend to absorb moisture.

The Adventurer 4’s print bed is flexible and removable, so you can lift off the entire bed and bend it to remove a print. That’s much easier than having to pry away at a fixed print bed. FlashForge includes a second print bed, so you can start a second print going as soon as the first print is removed. That’s a big plus for a busy 3D printer that needs to keep the output coming. In addition, the first thing that shows on the printer control screen when a print is done is a dialog box asking if you want to print the same object again.

You control the Adventurer 4 through a simple touch-screen on the left side of the front. This was easy to use, except when entering a password into the Wi-Fi setup. The tiny on-screen keyboard repeatedly detected two presses for one or mistook the letter that was typed. Otherwise, that panel’s fine for starting and monitoring a print, though.

I also had issues with Wi-Fi connectivity. On the FlashForge Adventurer 4. For unknown reasons, this printer refused to connect to my Wi-Fi network. After numerous attempts and ensuring that the passphrase was correctly entered, I gave up and used the wired ethernet connection instead, which worked without issues.

FlashForge Adventurer 4 review: Swappable print nozzles

One of the FlashForge Adventurer 4’s unique features is that you can swap out the device’s print nozzle — the business end of the printer that melts the filament. The printer comes with four nozzles with different diameters for the hole that the filament comes out of. In addition to the 0.3 and 0.6mm options, you get two 0.4mm nozzles, one of which works at 240 ℃, and one that works at 265℃ for materials that need higher temperatures.

The idea is that the bigger the diameter of the hole on the nozzle, the more filament can come out at a time. That allows for thicker layers of material, speeding up print times The different temperatures allow for different materials. Some filaments need higher temperatures to melt, so the higher temperature nozzle lets you use materials like Nylon.

Swappable nozzles definitely makes the Adventurer 4 more flexible than most 3D printers, but the process of changing nozzles is rather finicky and very manual. You turn the printer off, release the clips that hold the nozzle in place, pull the nozzle assembly out, then cut the filament to release the nozzle assembly. You then push the filament into the new nozzle before pushing everything back into place until the clips re-engage and lock it in place. You then turn the printer back on and use the manual controls to forward the filament until it comes out of the nozzle. Finally, you have to use the controls to enter a temperature offset, a value that FlashForge writes on the packaging of the nozzle that is the difference between the temperature measured by the sensor on the nozzle and the real temperature it reaches.

That’s a significant hassle, and it is possible to use the wrong nozzle without realizing it: the printer does not detect the type of nozzle installed and will try and print with a different one to the specified one installed.

Compare that to the automated nozzle change process of the Ultimaker S5, which detects the installed print nozzle and automates the process of removing and replacing the filament. Ultimaker’s approach involves a lot less hassle if you are frequently using the different print nozzles for different prints.

FlashForge Adventurer 4 review: Setup

The Adventurer 4 is a very simple printer to set up — you just take the 3D printer out of the box, remove the orange tape that holds the doors closed, and remove a few pieces of foam that hold the print head in place during shipping. Once that’s done, you can load the included 1KG of filament into the printer (our test unit came with red filament) and run the calibration setup.

This is where the setup process gets a bit less hassle-free. Many 3D printers have a self-leveling feature, where the printer automatically detects the print bed using a sensor on the print head; on the Adventurer 4, though, you end up doing a lot of the work yourself. If you select the automatic bed leveling, the printer moves the print head to nine different spots on the print bed. At each, you use the touch-screen control to move the print head up and down by fractions of a millimeter until you can just slide an included piece of mylar between the print head and the bed, indicating that there is the required tiny gap between the two.

Once you’ve done this for nine points on the print bed, the printer calculates any bumps or bend to the print bed and adjusts for them while printing. It’s an odd combination of manual and automatic that feels out of place in a sophisticated, automated printer like this.

Loading the filament is a fairly simple process. You mount the filament spool on the hook in the space on the right of the printer and push the end of the filament into the feeder. With the click of a button, the feeder grabs the filament and pushes it up through the tube into the print head. Once you see the melted filament coming out of the Adventurer 4’s print head, you hit the stop button and you are ready to print.

FlashForge Adventurer 4 review: Controls

You operate the Adventurer 4 through the on-device controls or through a network-connected app. To use features like the 3D printer’s built-in camera, you have to use the FlashPrint software, available for Mac and Windows. Alternatively, you can create prints using software like Cura and saved to USB drives for printing.

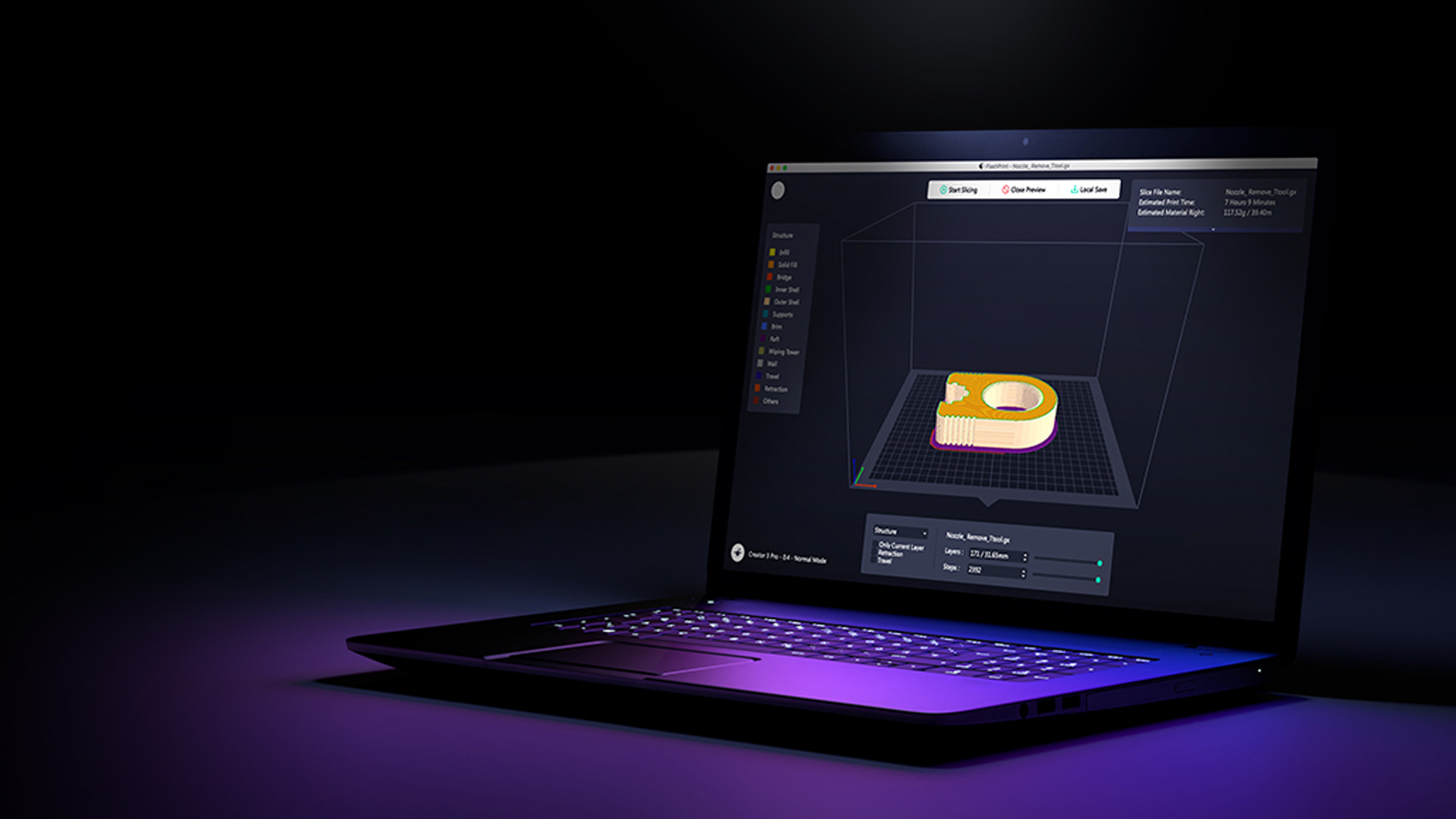

FlashPrint is a decent package for loading and preparing 3D prints. It supports a wide range of formats and offers a good selection of features. Once loaded, models can be scaled, stretched, duplicated, and otherwise jiggered around for printing. They can also be sliced — useful if you want to print a large model in parts. The program can also automatically arrange a group of models for best printing and provides extensive control over the creation of supports that hold the model in place.

Once you have the model prepared, you click on the slice button, which chops the model into layers that the FlashForge Adventurer 4 will build one by one and creates the file that tells the printer where to move and when to squirt out the filament. When this process is done, you can preview the print layer by layer, which is useful for spotting any potential problems with your print.

Finally, you can send the file to the printer and start the print, either by saving it to a USB drive or sending it over the local network. For the latter, you can observe the print in progress through the camera built into the Adventurer 4, albeit only at a rather low 640 x 480 pixel resolution. This camera can also capture time-lapses that are saved on the printer, but again the low resolution makes for grainy videos that don’t really let you see how the print is progressing.

The only lighting inside the Adventurer 4 is a single LED on the print head, so you don’t see that much via the camera unless there are other lights on. I ended up putting a small LED aquarium light on the top of the printer to provide more illumination.

The FlashPrint software also allows you to connect to multiple 3D printers and send a print file to all of them at once. That’s a useful feature if you are serious about printing and want to produce multiple prints at once, but it doesn’t allow for multiple users or clients, so it will be of limited use in a school or other multi-user environment. If you need more control over the printer or want to provide access to multiple users, the Adventurer 4 can work with two cloud printing services — Polar 3D and FlashCloud, Flashforge’s own cloud printing service. These are better options than FlashPrint for classroom or office use, but we didn’t test them extensively.

FlashForge Adventurer 4 review: Print materials

The combination of swappable print nozzles and a heated print bed means that the Adventurer 4 can handle a huge range of materials, from the standard PLA and ABS to more exotic materials like medical-grade Nylon, PETG or transparent materials such as T-Glase. The printer’s nozzles work up to 265℃, while the heated print bed can go up to 110℃, which also increases the number of printer materials the Adventurer 4 can support.

The Adventurer 4 does not require filament from any particular manufacturer: there is no sensor to detect a material tag such as is often seen on printers from manufacturers like XYZPrinting. So, you can use any filament that is 1.75mm in diameter.

FlashForge Adventurer 4 review: Print speed

The Adventurer 4 offers an average print speed compared to other 3D printers we’ve tested. Our Thinker test model took between 3 hours and just more than 10 to print, depending on the size of the print nozzle you use.

Choosing a print nozzle for the FlashForge Adventurer 4 comes down to a compromise between quality and speed: the larger the output of the print nozzle, the quicker the print because it can squeeze out more filament at a time.

We test the speed of a printer by timing how long it takes to produce a 4-inch high print of our Thinker model, and with the Adventurer 4’s largest 0.6mm nozzle in place, this took 3 hours and 25 minutes. The same print with the 0.3mm nozzle took 10 hours and 37 minutes, nearly three times as long. The difference is because of the number of layers that had to be printed: the 0.6mm version had 444 layers, while the 0.3mm version had 850 layers.

FlashForge Adventurer 4 review: Print quality

The FlashForge Adventure 4 produced excellent quality prints across the board, managing to print all of the complex models that we use for testing without any major issues.

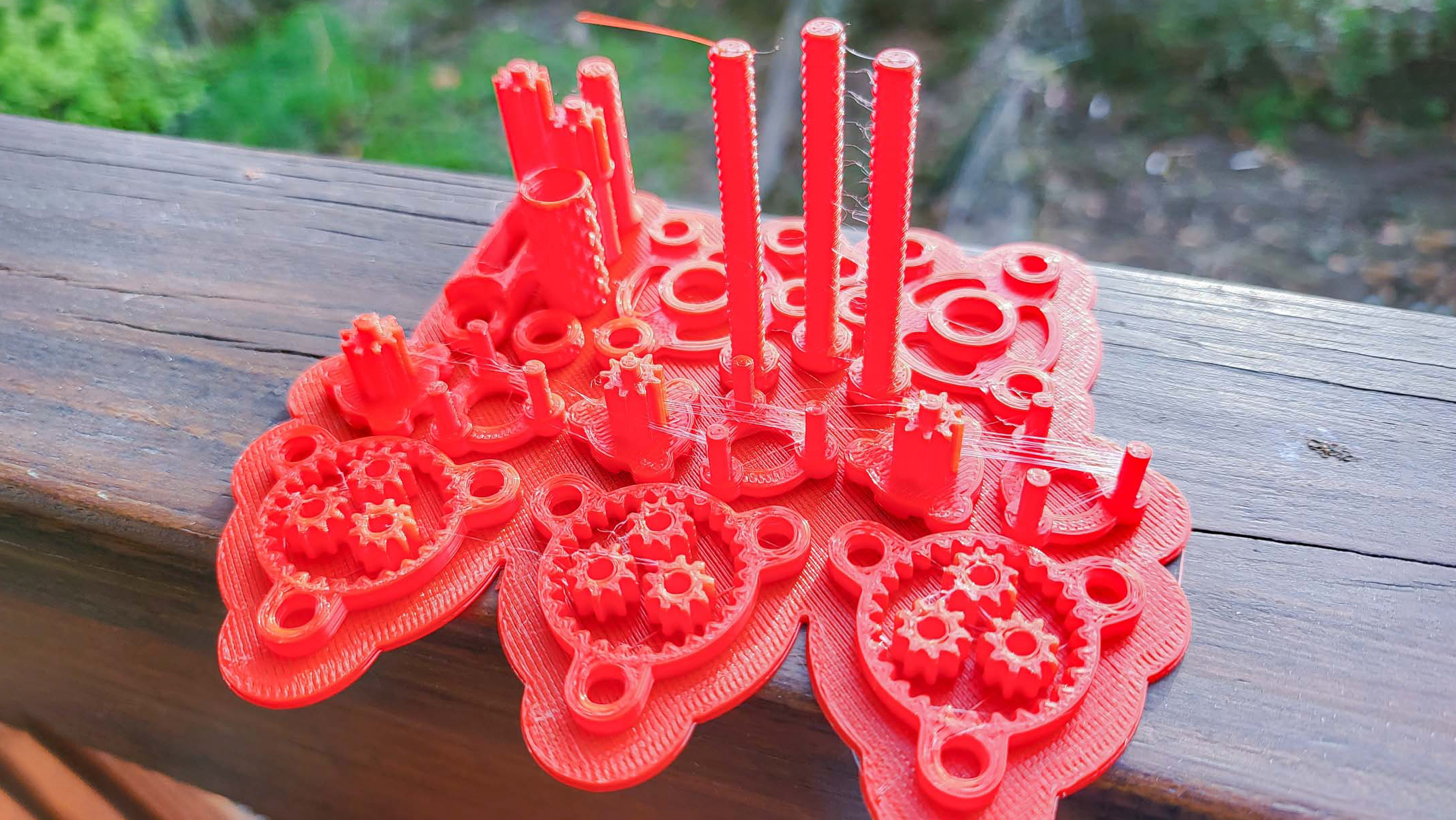

The only flaw we found was a tendency to produce stringy filaments of material when printing with PLA, which made some of the prints look like they had been playing host to a clan of spiders.

This is caused by insufficient retraction, where the printer should pull the filament back into the print nozzle when it is moving it from one part of the print to another. If it doesn’t retract enough, some filament stays at the end of the nozzle, stretching out into a thin string of filament that sticks to the print.

These strands of filament are more of an annoyance than a problem, though; you can easily remove them with a sharp knife.

FlashForge Adventurer 4 review: Verdict

The FlashForge Adventurer 4 gets close to being the ideal 3D printer: feed it a 3D model, leave it to work and it will produce a decent 3D print. Unfortunately, the Adventurer 4 isn’t quite perfect. I found issues with the software, such as the inability to connect to my Wi-Fi network and the hardware, such as the manual way you have to calibrate and swap print nozzles.

These issues aside, the FlashForge Adventurer 4 is a great pick for the serious 3D printer user who wants to print and print and print without hassle. And the sub-$1,000 price is tough to beat as well.

For all the latest Technology News Click Here

For the latest news and updates, follow us on Google News.