World first forensic tool for fire-damaged concrete structure

The National Fire Protection Association (NFPA) reports that there were 490,500 structure fires in the U.S. in 2020. However, people mostly struggles with the aftermath of the fire-damage. Structure fires caused $12.1 billion in property damage in 2020. How do we determine whether to rebuild or repair the fire-damaged structure? The Korea Institute of Civil Engineering and Building Technology (KICT) developed the world first forensic tool for fire-damaged concrete structure.

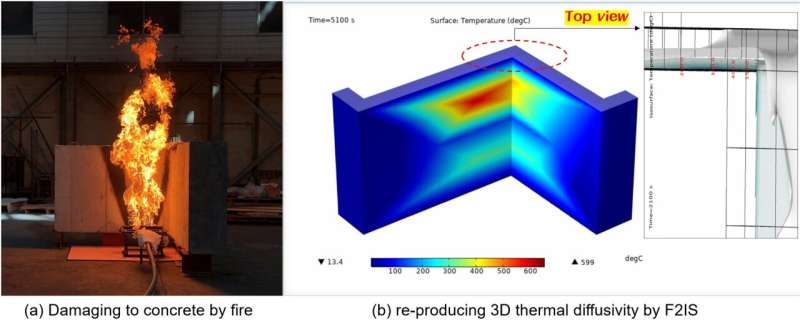

Generally, when concrete is exposed to fire, hydration products in a cement matrix are chemically decomposed. It leads to cracks, dramatic deterioration of strength and even end of its service life as structure. However, there is no widely accepted technique that can precisely evaluate the level of damage, due to fire. Various techniques are introduced in research papers, such as Visual observation, compression test, UV spectrum, oxygen measurement, but none of these can give a scientific clue whether the structure in fire scenes should be replaced or repaired. This is because their results are not always accurate, not re-producible and thereby not applicable to actual fire scenes.

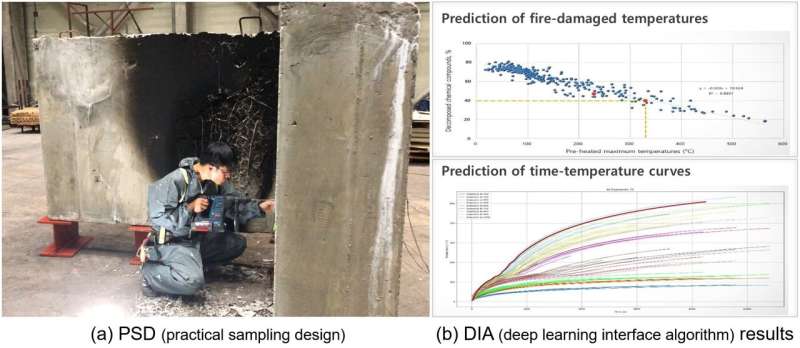

A research team led by Dr. Youngsun, Heo of Department of Fire Safety Research at KICT has developed the F2IS (fire forensic investigation of structure) tool that can answer the questions above. By only taking samples of 1 ~ 2g at every 10 mm depth of fire-damaged concrete, it can produce valuable outputs. For example, F2IS could successfully predict the fire-damaged temperature with over 80% accuracy, and time-temperature curves at the surface of concrete. They can re-produce thermal diffusivity by adopting three-dimensional simulation technique.

To produce the final outputs, F2IS follows the series of protocol. It starts with entering a fire scene, followed by practical sampling design (PSD) for fire-damaged concrete structure; experimental design (ED) for selecting appropriate chemical devices for analyzing specific samples; chemical profiling algorithm (CPA) for singling out the key features from chemical result and finally deep learning interface algorithm (DIA) for comparing the CPA results and the standard data pre-stored in a big data platform.

With a F2IS tool, it takes less than two weeks to complete the whole procedure of PSD, ED, CPA and DIA. This can minimize the unexpected payout and support business continuity. The high accuracy and transparency of the F2IS tool can also put out the tension between the landlord and the one who is responsible for fire as well as reducing liability of insurance companies. In addition, the output of re-producing thermal diffusivity by F2IS can contribute to narrow down the one definite fire scenario among many others, concluded by fire investigators.

Dr. Heo said, “After fire exposure, service life of concrete structure can drop within two weeks, depending on the damage level. The higher the volume of pores in concrete arising from fire, the faster is the dramatic reduction of life expectancy. If the structure is not going to be rebuilt, immediate diagnosis and subsequent repairing work should be proceeded even when there is minor damage.”

The research team registered the patent on the original technology, and plans to explore companies in demand to commercialize the F2IS tool for evaluating fire-damaged concrete in fire scenes. In addition to this technique, the team also plans to develop a rehabilitation system that can chemically cure the decomposition of hydration products and physically fill the cracks, due to fire, which in turn can recover the remaining service life of fire-damaged concrete structure. The patent was approved Aug. 17, 2021.

Fibers from old tires can improve fire resistance of concrete

Provided by

National Research Council of Science & Technology

Citation:

World first forensic tool for fire-damaged concrete structure (2021, November 15)

retrieved 15 November 2021

from https://techxplore.com/news/2021-11-world-forensic-tool-fire-damaged-concrete.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.

For all the latest Technology News Click Here

For the latest news and updates, follow us on Google News.