New method reduces carbon emissions from zinc oxide rotary kilns, boosting profits for zinc smelting industry

The zinc smelting industry is facing new challenges in meeting China’s carbon peak and carbon neutrality targets. To address these challenges, researchers from Central South University in China have developed a control method that reduces carbon emissions from zinc oxide rotary kilns while maintaining high profits. Their findings have been published in the journal Engineering.

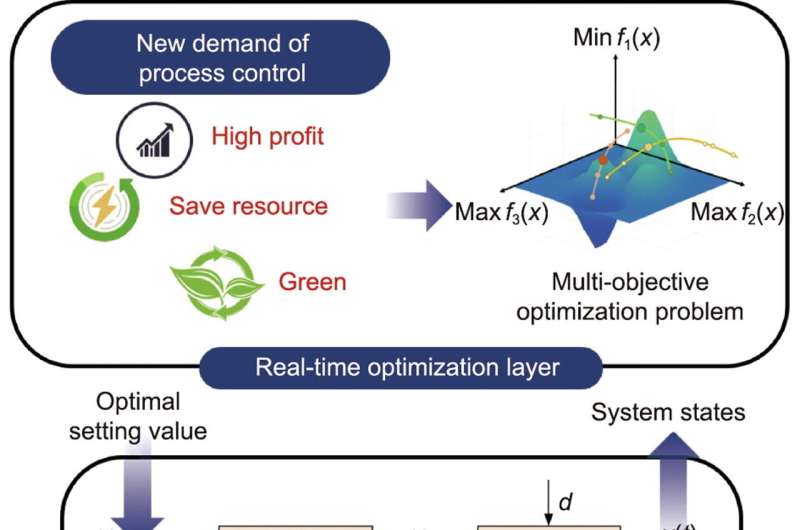

Zinc oxide rotary kilns play a crucial role in the zinc smelting process. However, traditional stability control methods are no longer suitable for the industry’s multi-objective control tasks. In their paper, Keke Huang’s research team proposes a multi-objective adaptive optimization model predictive control (MAO-MPC) method based on sparse identification.

The researchers first formulated and solved a sparse regression problem to obtain a reduction model using a large amount of data collected from a computational fluid dynamics (CFD) simulation model. This reduction model overcomes the high computational complexity of traditional CFD models, enabling real-time computation of the zinc oxide rotary kiln dynamics.

The proposed control method consists of a two-layered framework: real-time optimization (RTO) and model predictive control (MPC). In the RTO layer, an optimization problem is set up to achieve optimal operation performance and the lowest possible resource consumption. By solving this problem in real time, an optimal setting value is sent to the MPC layer, ensuring that the zinc oxide rotary kiln always operates in an optimal state.

The experiments conducted by the research team demonstrate the strength and reliability of the proposed method. It not only reduces the usage of coal but also maintains high profits for the industry. The control method offers a promising solution for zinc smelting companies to meet China’s carbon reduction goals and contribute to a greener future.

Nan Zhang, editor of the subject of chemical, metallurgical, and materials engineering of Engineering, commented, “This MAO-MPC method provides an effective approach for reducing carbon emissions from zinc oxide rotary kilns. By optimizing the process in real time, the zinc smelting industry can achieve significant reductions in coal consumption while maintaining high profits. This research has the potential to revolutionize the zinc smelting industry and contribute to China’s carbon neutrality goals.”

The research team’s work opens up avenues for further study, including improving the accuracy of first-principles models and designing optimization objective functions to enhance the performance of rotary kilns.

More information:

Ke Wei et al, Multi-Objective Adaptive Optimization Model Predictive Control: Decreasing Carbon Emissions from a Zinc Oxide Rotary Kiln, Engineering (2023). DOI: 10.1016/j.eng.2023.01.017

Provided by

Engineering

Citation:

New method reduces carbon emissions from zinc oxide rotary kilns, boosting profits for zinc smelting industry (2023, September 29)

retrieved 30 September 2023

from https://techxplore.com/news/2023-09-method-carbon-emissions-zinc-oxide.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.

For all the latest Technology News Click Here

For the latest news and updates, follow us on Google News.