A 4D printer for smart materials with magneto- and electro-mechanical properties

Researchers at Universidad Carlos III de Madrid (UC3M) have created software and hardware for a 4D printer with applications in the biomedical field. In addition to 3D printing, this machine allows for controlling extra functions: programming the material’s response so that shape-changing occurs under external magnetic field, or changes in its electric properties develops under mechanical deformation. This opens the door to the design of soft robots or smart sensors and substrates that transmit signals to different cellular systems, among other applications.

This research line focuses on the development of soft multifunctional structures, which consist of materials with mechanical properties that mimic biological tissues such as the brain or skin. In addition, they are capable of changing their shape or properties when actuated via external stimuli, such as magnetic fields or electric currents.

Until now, this team of researchers had made several advances in the design and manufacturing of these structures, but they were very limited in terms of shape-design and programming of intelligent responses. The work presented in their latest study, published in the journal Advanced Materials Technologies, has allowed them to open up new possibilities by developing a novel 4D printing methodology.

“This technology allows us to not only control the way we print three-dimensional structures, but also to give them the ability to change their properties or geometry in response to the action of external magnetic fields, or the ability to modify their electric properties when they deform,” explains one of the researchers, Daniel García González, head of the ERC 4D-BIOMAP (GA 947723) project and associate professor in UC3M’s Department of Continuum Mechanics and Structure Theory.

This type of printing is complex since the material to be extruded transitions from liquid to solid during the printing process. It is therefore necessary to understand the material dynamics to adapt the manufacturing process and obtain a material which is sufficiently liquid when it flows through the printer nozzle but, at the same time, solid enough to maintain a specific shape.

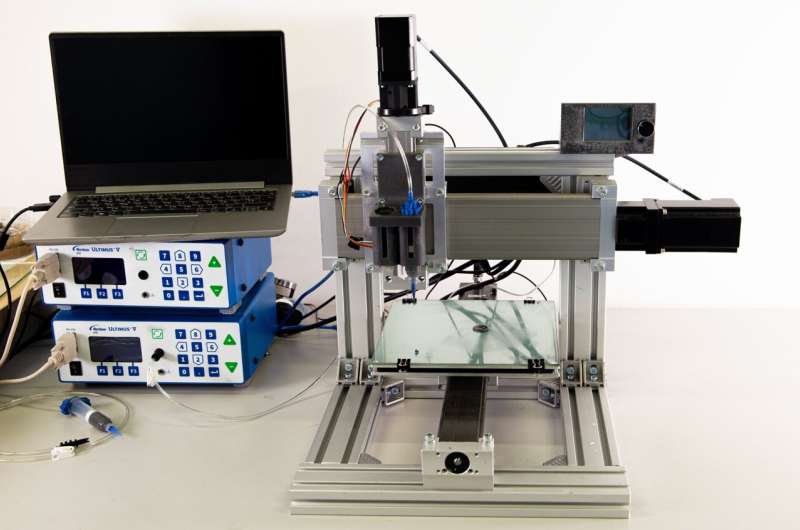

To this end, they have developed an interdisciplinary methodology that combines theoretical and experimental techniques allowing them to build the printing device from scratch, both the physical part of the device (the hardware) and the computer programs that allow it to be controlled (the software).

A self-healing material

The researchers have also developed a new material concept that is capable of healing itself autonomously without the need for external action, according to another recent publication in the journal Composites Part B: Engineering. “This material consists of a soft polymer matrix embedded with magnetic particles with a remanent field. For practical purposes, it is as if we had small magnets distributed in the material, so that, if it breaks, when the resulting parts are brought together again, they will physically join recovering their structural integrity,” says Daniel García González.

Thanks to these advances, which have led to several registered patents, these scientists have been able to print three types of functional materials: some that change their shape and properties in response to external magnetic fields; others with self-healing capability; and others whose electrical properties (conductivity) vary according to their shape or deformation. With the first type of material, they have developed smart substrates to transmit forces and signals to cellular systems, so that they can influence biological processes such as cell proliferation or migration. These materials can also be used to design soft robots whose performance can be controlled by magnetic fields.

The combination of materials with self-healing capabilities and whose electric conduction properties vary with deformation opens up enormous possibilities in the development of sensors. “We can think of sensors that, attached to our body, collect information about our movement from variations in electric conductivity. In addition, the material’s self-healing capability allows the design of sensors with binary signals. For example, if we have had a knee injury and need to limit rotation to a maximum value, we can incorporate a small band of this material over our joint,” says Daniel Garcia González.

“This way, when we exceed this maximum rotation, the material will break showing an abrupt change in its electric properties, thus providing a warning signal. However, when returning the knee to a relaxed state, the material’s healing capability will result in recovery of the electric signal. This way we can monitor our movements and warn of risky conditions after surgery or during rehabilitation periods.”

More information:

Maria Luisa Lopez‐Donaire et al, Computationally Guided DIW Technology to Enable Robust Printing of Inks with Evolving Rheological Properties, Advanced Materials Technologies (2023). DOI: 10.1002/admt.202370012

Daniel Garcia-Gonzalez et al, Hard-magnetic phenomena enable autonomous self-healing elastomers, Composites Part B: Engineering (2022). DOI: 10.1016/j.compositesb.2022.110357

Citation:

A 4D printer for smart materials with magneto- and electro-mechanical properties (2023, March 7)

retrieved 7 March 2023

from https://techxplore.com/news/2023-03-4d-printer-smart-materials-magneto-.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.

For all the latest Technology News Click Here

For the latest news and updates, follow us on Google News.